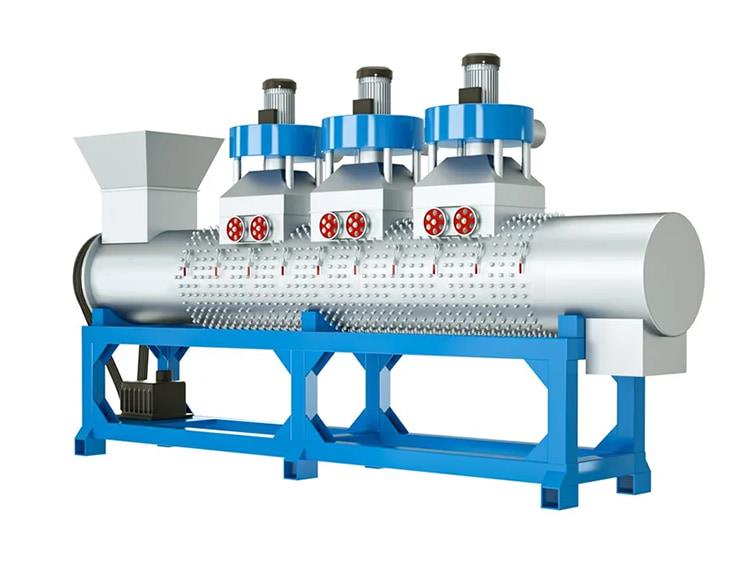

Dry Label Remover Machine

- Efficiency and Labor:It saves labor, has high efficiency, and the workload completion rate can reach approximately 98%. This dry label remover machine significantly reduces labor costs compared to manual operations, making it an ideal choice for PET bottle recycling factories looking to optimize efficiency.

- Capacity and Production Capacity:It has a large capacity with a production capacity ranging from 500 to 2000 KG/H, and multiple specifications are available. The reasonably designed structure enhances the output. This high-capacity PET bottle label remover machine can meet the diverse production needs of different-scale PET bottle recycling lines, ensuring stable and efficient operation.

- Cutter - Related:It is equipped with more than 300 specially designed alloy steel blades, which are durable. Some parts adopt diamond wear-resistant blades, whose wear-resistant service life is twice that of alloy cutter particles. The cutter heads are made of high-alloy materials, featuring a large welding area, high hardness, wear resistance, and durability. Moreover, the cutter heads do not need to be replaced in a whole row; only the damaged single cutter head needs to be replaced. The high-quality cutters of this dry label remover machine ensure long-term stable operation, reducing the frequency of maintenance and replacement.

- Label Removal and Separation Effect:It has a high label removal rate. The new machine can be used after installing two-thirds of the blades, and the distance between the moving knife and the door knife can be adjusted, so the label removal effect can reach more than 95% or even more than 98%. The separation rate is as high as 99.5% or more. It adopts a new type of detachable air suction separator, which solves the problem of working on rainy days. The separated paper contains no bottle caps or broken bottles, only a small amount of bottle rings. This PET bottle label remover machine ensures excellent label removal and separation performance, providing high-quality raw materials for the subsequent PET bottle crushing and cleaning process.

- Other Advantages:The blades and cylinder walls are made of thick-walled materials, extending the service life by 3 to 4 years. The rotation speed of the label remover machine is reduced, which lowers the bottle mouth breaking rate without affecting the label removal rate and output. The machine adopts a staggered opposite door, which is convenient for checking the damage of the cutter heads inside the barrel. The machine is equipped with an additional automatic device, enabling easy label removal for both intact bottles and flat bottles. The length of the machine can be customized according to the customer's daily output. This customizable dry label remover machine can be tailored to the specific production needs of different customers, enhancing its adaptability in various PET bottle recycling production lines.

Overview

The PET bottle label remover machine is specifically designed to remove labels from PET bottles, milk bottles, and other similar containers. It can replace manual label removal, meet the high-capacity requirements of production lines, and improve the efficiency of PET bottle recycling lines. As a crucial process before crushing in the PET bottle recycling production line, it can reduce the PVC content in PET flakes, prepare for the subsequent crushing and cleaning of PET bottle materials, and generate good economic and social benefits.

Working Principle:

After beverage bottles or plastic bottles are put into the hopper, the alloy steel cutter in the label remover machine makes a cut on the bottle label. The blades, which are welded on the main shaft at a certain angle to the center line of the main shaft and rotate in a spiral manner, convey the waste bottles to the discharge port. The toothed cutters or alloy cutter particles on the blades peel off the labels. Then, wind energy or a wind box separation chamber is used to separate the labels from the bottle bodies. The label paper is blown out, and the plastic bottles without labels fall down, which are then sent to the plastic crusher for further processing.

Application Scope:

It is suitable for PET bottle recycling and processing factories, plastic sorting and recycling factories, and meets the production needs of the PET bottle label removal section in the PET cleaning line. This PET bottle label remover machine is a necessary equipment for enterprises engaged in PET bottle recycling and processing, helping them improve the overall efficiency of the production line.

Maintenance:

Regularly check the wear condition of the alloy steel cutters or diamond wear-resistant blades, and replace the damaged cutter heads in a timely manner; check whether the separation devices of the machine, such as the air suction separator, are working normally; regularly clean the interior of the machine to avoid the accumulation of label debris affecting the machine operation; check whether the transmission components of the machine, such as the main shaft, are operating normally, and add lubricating oil appropriately. Proper maintenance of this dry label remover machine can ensure its long-term stable operation and extend its service life, reducing production costs for enterprises.

Technical Parameters

Drum Screen

- High screening efficiency: The drum support adopts an integral shaft structure, which ensures stable and reliable operation and high screening efficiency. This high - efficiency drum screen can greatly improve the material processing speed in production lines.

- Simple structure: The overall structure is simple, with few failures and high cost - effectiveness; the internal drum screen accessories adopt a split design, making replacement and maintenance fast and convenient. The simple structure of this drum screen reduces the maintenance cost for manufacturers and enterprises.

- Not easy to clog: It adopts the rolling conveying principle, with small friction coefficient, light wear, and the screen holes are not easy to clog. The anti - clogging performance of this drum screen ensures long - term stable operation of the production line.

- Energy saving: It adopts reduction transmission, with high transmission efficiency, small power, and energy saving. This energy - saving drum screen helps enterprises reduce energy consumption and production costs, which is in line with the development needs of energy - saving production.

- Good sealing: The drum body adopts an effective sealing structure, which does not produce dust and cause pollution; the screening cylinder can be closed, making it easy for closed dust collection. The good sealing performance of this drum screen meets the environmental protection requirements of modern enterprises and creates a good working environment for workers.

- High reliability: The whole machine has high reliability, with less one - time investment; it operates reliably and has a long service life. The high reliability of this drum screen ensures that enterprises can recover the investment cost quickly and obtain long - term economic benefits.

- Strong customization: Different screen materials and screen hole sizes can be adopted according to customer requirements, with high screening efficiency and low maintenance cost. The strong customization of this drum screen can meet the specific screening needs of different industries and enterprises, such as stone yards, coal mines, chemical plants, etc.